BEIJING, Nov. 5, 2020 — WiMi Hologram Cloud Inc. (Nasdaq: WIMI) ("WiMi" or the "Company"), a leading augmented reality ("AR") service provider in China, announces that its wholly-owned subsidiary, VIYI Technology Inc. ("VIYI Technology"), has entered into an agreement for the acquisition of 100% equity interests of Singapore-based Fe-da Electronics Company Pte Ltd….

300mm Fab Spending to Boom Through 2023 With Two Record Highs, SEMI Reports

Chip industry to add 38 new 300mm fabs by 2024 MILPITAS, California, Nov. 3, 2020 — 300mm fab investments in 2020 will grow by 13% year-over-year (YoY) to eclipse the previous record high set in 2018 and log another banner year for the semiconductor…

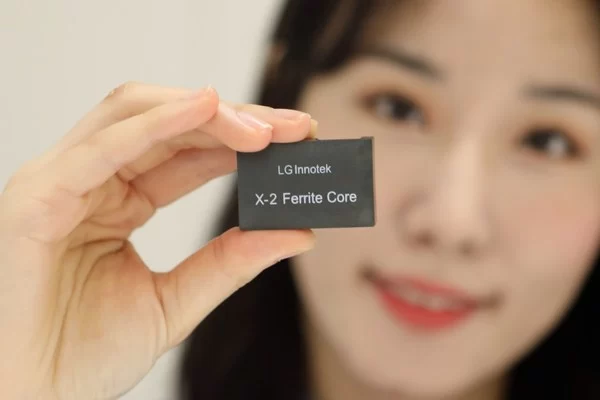

LG Innotek’s high-efficiency ferrite, Advancing the Era of Ultra-Slim OLED TVs Under 2cm Thick

Ultra-slim TV and lightweight vehicles with improved energy efficiency Reduced development period to 1/4 of projected time, achieving world-class performance Internalization of core materials to provide differentiated customer value SEOUL, South Korea, Oct. 18, 2020 — LG Innotek announced on the 19th that it has successfully…

RS Components launches 94% efficient POL converters covering most standard bus and battery voltages

Versatile switching regulators are drop-in replacements for LMxx devices SHANGHAI, Oct. 16, 2020 — RS Components (RS), a trading brand of Electrocomponents plc (LSE: ECM), a global omni-channel solutions partner for industrial customers and suppliers, has added the new TRACO Power TSR-WI Series of non-isolated POL (point of load) DC/DC…

ChipMOS REPORTS SEPTEMBER 2020 AND 3Q20 REVENUE, REPRESENTING A QUARTERLY SIX YEAR HIGH

HSINCHU, Taiwan, Oct. 8, 2020 /PRNewswire-FirstCall/ — ChipMOS TECHNOLOGIES INC. ("ChipMOS" or the "Company") (Taiwan Stock Exchange: 8150 and NASDAQ: IMOS), an industry leading provider of outsourced semiconductor assembly and test services ("OSAT"), today reported its unaudited consolidated revenue for the month of September 2020 and for the third quarter ended September 30, 2020. All U.S….

Media Alert: Supermicro Delivers the Latest Product Updates in Live Presentations at Nikkei X-TECH EXPO 2020

Supermicro’s Japan Leadership Presents the Latest Storage System Innovations and Storage Solutions for Enterprise, Data Centers, and Cloud Markets TOKYO, Oct. 7, 2020 — Supermicro will present at the virtual Nikkei X-TECH EXPO 2020 its latest server and storage system for AI, 5G, IoT, and enterprise markets. Nikkei X- TECH…

Picosun’s ALD technology boosts UVC LED performance

ESPOO, Finland, Sept. 24, 2020 — Picosun Group, the leading supplier of AGILE ALD® (Atomic Layer Deposition) thin film coating technology, reports excellent results in UVC (ultraviolet-C) LED performance, achieved with the company’s ALD solutions. Excellent reliability and lifetime improvements of UVC LEDs have been obtained at Picosun’s customer and…

AUTOCRYPT Announces Official Partnership with NXP for Integrated V2X Security Solutions

SEOUL, South Korea, Sept. 24, 2020 — AUTOCRYPT Co., Ltd., a leading V2X and autonomous vehicle security solutions provider, announced its partnership with NXP Semiconductors in several automotive security related applications beginning with secure V2X. As an official partner of NXP, support for AutoCrypt V2X will be streamlined across NXP’s V2X-related offerings,…

Seoul Semiconductor’s WICOP Bi-Color LEDs Are Shining in the Headlamp of Audi A4 Model Year 2020

ANSAN, South Korea, Sept. 22, 2020 — Seoul Semiconductor Co., Ltd. ("Seoul") (KOSDAQ 046890), a leading global innovator of LED products and technology, announced that it has supplied WICOP Bi-color (2 colors in one package) LED products for the daytime running lights and front…

QuantumClean and ChemTrace Show How to Reduce Cost of Ownership at SEMICON Taiwan

HAYWARD, California, Sept. 15, 2020 — Ultra Clean Holdings, Inc. (Nasdaq: UCTT), today announced that its Service Businesses, QuantumClean and ChemTrace, will demonstrate how their ultra-high purity chamber tool part cleaning, proprietary coatings and micro-contamination analytical testing can help reduce Cost of Ownership (CoO) for wafer fabs and OEMs. QuantumClean…