SHANGHAI, Oct. 7, 2022 /PRNewswire/ — Hesai has officially announced its monthly delivery of the AT128 lidar exceeded 10,000 units, making Hesai the world’s first automotive lidar company to reach this milestone.

“10,000” is an important milestone for both Hesai and the industry, marking the beginning of automotive lidar’s mass production and delivery in the global market. Hesai also maintains the highest market share in the global L4 autonomous driving market.

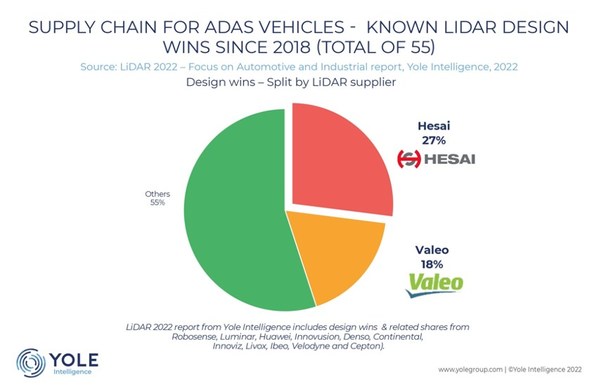

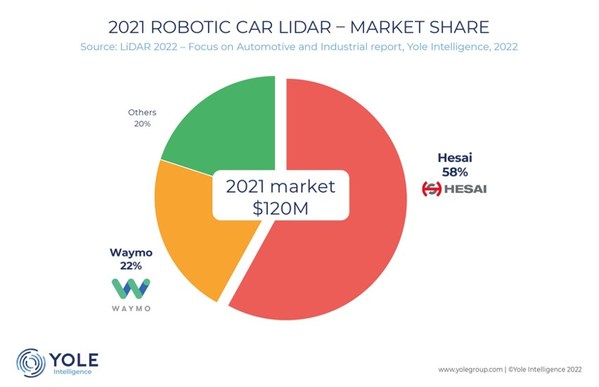

According to the “Lidar for Automotive and Industrial Applications 2022 Market and Technology Report ” released by Yole Intelligence in August, with the strong emergence of China’s intelligent driving industry, Chinese manufacturers such as Hesai have become important players in the global lidar market. Among the lidar manufacturers, Hesai ranks first in ADAS design wins, L4 autonomous driving lidar market share, and total revenue for automotive lidar.

Proprietary technology behind high-demand lidar

Hesai’s first mass-produced ADAS long-range main lidar, AT128 is not the first hybrid solid-state lidar to enter the market. However, it immediately won multiple contracts from leading automakers after its release, including Li Auto, JiDU, HiPhi, and Lotus. “AT128 has excellent comprehensive performance among currently mass-produced, automotive-grade lidars,” said Li Xiang, CEO of Li Auto.

Hesai’s exceptional R&D capability played a key role in achieving such high lidar performance. Unlike other manufacturers who try to reduce costs by cutting the number of lasers and complicating the scanning module, Hesai took a unique but harder path: keeping the 128 channels, and integrating hundreds of components to form optimized lidar architecture through proprietary technology.

Hesai’s proprietary technology has three significant technical advantages:

The first is higher performance. A “genuine 128-channel” lidar can conduct ultra-high precision scanning of the environment, forming uniform and unstitched point cloud that help vehicles “see” the 3D world clearly in real-time.

The second is higher reliability. Reducing the number of individual components in a lidar improves mass production reliability. 128 laser channels also provide higher safety redundancy. Even if one laser channel fails, the rest will continue to operate to ensure normal function of the lidar.

The third is higher production consistency. By enhancing components integration, it minimizes manual assembly to avoid human errors, which significantly increases production efficiency and consistency.

Highly automated production line with 60-second cycle time

In addition to the proprietary technology, another strategic adavantage for Hesai is its in-house manufacturing. Hesai believes that rapid iteration and quality control are crucial for automotive lidar. Self-built factory enables a higher degree of control during each manufacturing step, allowing timely optimizations to ensure large-scale, high-quality mass production and delivery.

Hesai’s factory adopts the most advanced manufacturing technology and intelligent cloud service. It deploys a large number of intelligent industrial robots to automate over 100 production processes, achieving a 90% automation rate of the entire production line. It also has a 60-second cycle time, which means that on average, a qualified lidar unit rolls off the production line every 60 seconds.

To achieve strong mass-production and delivery capability that satisfies global OEMs’ requirements, Hesai also invested nearly 200 million US dollars in its “Maxwell” intelligent factory. It has a planned annual production capacity of over one million units. The factory is expected to enter operation by 2023.

![]() View original content to download multimedia:https://www.prnewswire.com/news-releases/hesai-becomes-the-worlds-first-automotive-lidar-company-to-reach-10-000-units-monthly-delivery-301643495.html

View original content to download multimedia:https://www.prnewswire.com/news-releases/hesai-becomes-the-worlds-first-automotive-lidar-company-to-reach-10-000-units-monthly-delivery-301643495.html