Infrared laser cleave technology enables ultra-thin-layer transfer from silicon substrates with nanometer precision, revolutionizing 3D integration for advanced packaging and transistor scaling…

EV Group and Dymek Company Form Joint Venture Company in Malaysia to Enhance Regional Customer Support

ST. FLORIAN, Austria and HONG KONG, May 23, 2023 — EV Group (EVG), a leading supplier of wafer bonding and lithography equipment for the MEMS, nanotechnology and semiconductor markets,…

Picosun delivers powder MEMS technology platform to Fraunhofer ISIT

ESPOO, Finland, Feb. 17, 2022 — Fraunhofer Institute for Silicon Technology (ISIT) has taken PICOSUN® P-300B ALD system into use as their powder MEMS technology platform. Fraunhofer ISIT PowderMEMS is…

ICCPP Ushers “Powder-free” Atomization Technology with Next-Generation GENE TREE Ceramic Cores

SHENZHEN, China, Sept. 18, 2021 — ICCPP, a global atomization company, has unveiled its first-ever ceramic core technology brand GENE TREE at the 2021 Nano-tech Ceramic Core Global Online Launch Conference on September 16. The release of GENE TREE marks a revolution in electric atomization R&D while also introducing a…

Evo successfully responds to e-commerce growth with Kӧrber and Locus Robotics

Sports retailer increases picking speed by 157% by deploying AMRs in just 53 days HAMBURG, Germany and WILMINGTON, Mass., Sept. 10, 2021 — Körber and long-time strategic partner Locus Robotics, the global leader in warehouse robotics, together are enabling evo to dramatically improve ecommerce order fulfillment…

Revolutionary X-ray Technology From Australia to Transform American Airport Security

SeaTac chosen for Micro-X Inc’s USA headquartersOfficial Opening at 10 am PDT, Friday May 28855 S 192nd Street, Suite B600, Seattle, WA 98148 With: Congressman Adam Smith, chair of the House Armed Services Committee Brigadier Hugh Meggitt representing Australian Defence Staff, Embassy of Australia Stephen Patterson,…

“I Love Being Pioneer”– Interview with Prominent WPI-MANA Researcher

TSUKUBA, Japan, Aug. 28, 2020 — The International Center for Materials Nanoarchitectonics (WPI-MANA), a unit of the National Institute for Materials Science (NIMS), welcomed Honorary Professor Hideo Hosono of Tokyo Institute of Technology as a NIMS Distinguished Fellow and the leader of the Electro-Active Materials Team. (Photo: https://kyodonewsprwire.jp/prwfile/release/M105739/202008183234/_prw_PI1fl_es00fXV1.jpg) Prof. Hosono,…

Welcome to NETX – Global Conglomerate Bellagraph Nova Group Launches Latest Technolgy Platform Focusing on AI + Robotics + Healthcare

PARIS, July 10, 2020 — Headquartered in Paris, France, the Bellagraph Nova Group (BN Group), the multi-national conglomerate overseeing 31 business entities across 100 countries is the world’s fastest growing 360 degree lifestyle platform. The BN Group is proud to announce its latest project…

KT and Hyundai Accelerate Digital Transformation with Smart Robots

– KT Invests 50 Billion Won for 10 Percent Equity in Hyundai Robotics –

– Intelligent Service Robots to be Jointly Developed for Market Entry –

– KT’s 5G, AI Capability to Sharpen Korea’s Industrial Competitiveness –

SEOUL, South Korea, June 18, 2020 /PRNewswire/ — KT Corp. (KRX: 030200; NYSE: KT), South Korea’s largest telecommunications company, announced it signed strategic cooperation and investment contracts with Hyundai Robotics, to speed up collaboration for digital transformation based on 5G, artificial intelligence (AI) and smart factory.

After KT and Hyundai Robotics contracts to speed up collaboration for digital transformation based on 5G, AI and smart factory, KT president Ku Hyeonmo and Hyundai Heavy Industries Holdings Senior Executive Vice President (SEVP) Chung Kisun are taking photo at the signing ceremony.

Under the contracts, KT will acquire a 10 percent equity stake in Hyundai Robotics, the leader in the Korean industrial robotics market, for 50 billion won.

KT also signed a business cooperation agreement with Hyundai Heavy Industries Holdings for joint efforts toward digital transformation.

The signing ceremony, held at the KT headquarters in central Seoul, was attended by KT President Ku Hyeonmo, Hyundai Heavy Industries Holdings Senior Executive Vice President (SEVP) Chung Kisun and Hyundai Robotics CEO Seo Yoo-seong, and other senior executives.

The two sides signed a memorandum of understanding in May 2019 and the new contracts solidify their ongoing collaboration to spread digital transformation based on 5G, AI and smart factory. They intend to quicken joint development of intelligent service robots, technological research in autonomous driving, and smart factory solutions.

"In the post-COVID 19 era, KT is prepared to contribute to strengthening the Republic of Korea’s industrial competitiveness and the transformation of our nation’s manufacturing industry, taking advantage of our 5G and AI capability in cooperation with Hyundai Heavy Industries Group," said KT President Ku. "Beginning with Hyundai Heavy Industries Group, we will do our utmost to expand digital transformation in diverse areas."

KT will undertake software development and applications related to intelligent service robots and autonomous driving, while Hyundai Robotics will be responsible for hardware development and manufacturing. This is expected to lead to the introduction of intelligent robots that not only provide hotel amenities but also serve food and beverages at restaurants, and cleaning patrol robots loaded with cleaning and security functions. For entry into the service robot market, the two parties also plan to develop collaborative robots for small factories and large franchise stores.

For a smart factory, KT will provide communication technology, cloud, ICT solutions, and related bundle products, while Hyundai Robotics will supply robots and relevant solutions. In particular, the combination of KT’s smart factory solutions, dubbed "5G Factory Makers," and Hyundai Robotics’ Hyundai Robot Management System (HRMS) is expected to heighten smart factory process analysis, production management and predictive maintenance. The toolkits of both sides will also be applied jointly for smart hospitals and logistics.

Along with its equity participation in Hyundai Robotics, KT will seek an exchange of human resources to help refine elevation of Hyundai Robotics’ competitiveness in robotics and smart factory.

"Beyond mere production, the competitiveness of manufacturers will be determined in the future by the ability of individual businesses to read market trends and transform themselves." said Chung Kisun, Senior Executive Vice President (SEVP) of Hyundai Heavy Industries Holdings. "Through expansive business cooperation with KT, we believe that not only Hyundai Robotics but the entire Hyundai Heavy Industries Group will be able to achieve digital transformation and thereby improve our competitiveness as leading enterprises in the world."

Hyundai Robotics, spun off from Hyundai Heavy Industries in April 2017, became a separate corporation specialized for robotics and smart solutions in May this year. It provides smart factory and smart logistics services, and has two subsidiaries – Hyundai Robotics Shanghai and Hyundai L&S (Logistics and Solutions). The company aims for an initial public offering in 2022.

In accordance with their business cooperation agreement, KT and Hyundai Heavy Industries Group will delineate details of their collaboration, particularly through a new senior committee on joint efforts in smart solutions, digital transformation, AI and ICT, as well as other business opportunities. The group will include KT President Ku and Hyundai Heavy Industries Holdings Senior Executive Vice President (SEVP) Chung Kisun.

Last year November, KT and Hyundai Heavy Industries Holdings conducted a joint presentation on their 5G-based business cooperation, focusing on smart factory and smart shipbuilding. In February this year, they launched "AI One Team," aiming to lift Korea to global leadership in AI, and two months later, KT and Hyundai Robotics introduced "N Bot," an upgrade from KT’s second-generation GiGA Genie hotel robot in terms of both function and design, at the Novotel Ambassador Seoul Dongdaemun Hotel. It was followed by the signing with Hyundai Construction Equipment of a memorandum of understanding for "joint development and commercialization of 5G smart construction equipment and industrial vehicle platform."

KT expects that its cooperation with Hyundai Heavy Industries Group will expand digital transformation into diverse industrial fields, eventually enhancing national competitiveness. To that end, KT is exerting corporation-wide efforts for digital transformation to help maximize efficiency and widen business opportunities of companies on the basis of its expertise in 5G network, AI, Big Data, cloud and ICT solution.

MEDIA CONTACTS

For inquiries, please contact our Global Media Relations Team at [email protected]

ABOUT KT CORPORATION (KRX: 030200; NYSE: KT)

KT Corp., Korea’s largest telecommunications service provider, reestablished in 1981 under the Telecommunications Business Act, is leading the era of innovations in the world’s most connected country. The company is leading the 4th industrial revolution with high speed wire/wireless network and new ICT technology. KT launched the world’s first nationwide commercial 5G network on April 3, 2019, after successfully showcasing the world’s first trial 5G services at the PyeongChang Winter Olympic Games in February 2018. This is another milestone in KT’s continuous efforts to deliver essential products and services as it aspires to be the number one ICT Company and People’s Company.

For more information, please visit our English website at https://corp.kt.com/eng/

Related Links :

https://corp.kt.com/eng

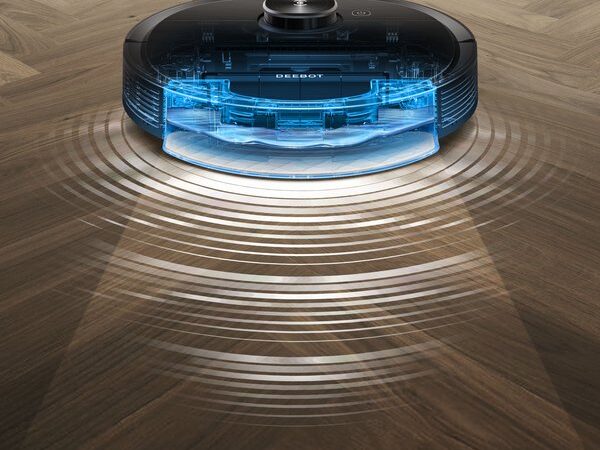

ECOVACS ROBOTICS Launches the DEEBOT OZMO T8 Family Putting AI to Work For a Better Looking Home

First family member DEEBOT OZMO T8 AIVI optimizes AI to speed up obstacle recognition as well as enhance mapping and navigation for state-of-the-art, hassle-free cleaning

SINGAPORE, May 25, 2020 /PRNewswire/ — ECOVACS ROBOTICS launched the DEEBOT OZMO T8 family, its latest series of high-end intelligent robotic vacuum cleaner. First family member DEEBOT OZMO T8 AIVI features ECOVACS’ optimized AIVI™ (Artificial Intelligence and Visual Interpretation) Technology for faster obstacle recognition, TrueMapping™ Mapping and Navigation Technology, and OZMO™ Pro for advanced mopping performance. In addition, its on-demand feature Video Manager makes the DEEBOT OZMO T8 AIVI a personal and powerful housekeeping robot, bringing users advanced interaction between human and robot by enabling them to reach to a new level of robotic vacuum cleaner user experience. The new DEEBOT OZMO T8 AIVI is also the winner of the internationally respected iF Design Award of 2020.

"With over 22 years of innovative technology development, ECOVACS ROBOTICS has driven the transition from traditional methods of home cleaning care to automated home care," said David Qian, CEO of ECOVACS ROBOTICS, "Our new DEEBOT OZMO T8 family gives consumers what they have been looking for, a high-end intelligent solution for a hassle-free cleaning experience."

Latest Optimized AIVI™ Technology – Sophisticated Obstacle Avoidance

With the latest optimized AIVI™ Technology, the DEEBOT OZMO T8 AIVI can recognize and avoid obstacles 200% faster with a predicted 60% reduction in entanglement rate compared to existing AIVI products, relying on machine learning to adapt to the user’s unique home environment. It also intelligently suggests extra cleaning based on its record of spots avoided, to offer a more thorough cleaning performance.

The DEEBOT OZMO T8 AIVI can automatically recognize objects including shoes, charging docks, cables, cloths, and socks to avoid obstacles and prevent the robot from getting stuck.

As the industry’s most intelligent robotic vacuum cleaner, further advanced AI-powered functions will be offered via OTA (Over the Air) Technology in the coming months, including automated detection of U-shaped chairs and rugs. For U-shaped chairs, the robot will make a single attempt to pass them, and for rugs the robot will automatically adjust roller brush speed to avoid getting stuck.

First-adopt Aerospace-standard dToF Detection Technology[1] Powers Brand-new TrueMapping™ to Enable Precise and Customized Cleaning

Compared with the previous generation of Smart Navi® 3.0, the TrueMapping™ laser-based mapping and navigation technology can detect a double distance and has four-fold precision to detect objects as small as two millimeters. With the new technology, DEEBOT OZMO T8 AIVI can now scan, map, and plan an efficient cleaning path in a large house faster and more precisely.

TrueMapping™ Mapping and Navigation Technology also offers users a more customized and intelligent cleaning experience. The DEEBOT OZMO T8 AIVI has Multi-floor Mapping Technology that can scan and store multiple maps of different levels of a user’s home. For first time cleaning, the robot automatically divides the whole cleaning environment into multiple areas based on the floorplan. Once the robot has identified the appropriate map, it can customize its cleaning process to each level. Furthermore, the upgraded Virtual Boundary™ can proactively provide recommendations for virtual walls around areas where it may easily become stuck, with the user only needing to click the confirmation on the ECOVACS Home App to accept the recommendations.

A Reliable Cleaning Partner with Powerful Vacuuming and Mopping Capabilities

The DEEBOT OZMO T8 AIVI provides powerful vacuuming and mopping capabilities, that can both be completed in one go. The four-step cleaning offers efficient vacuuming that won’t even miss dust in 4mm deep cracks. This new family member also includes an interchangeable enhanced mopping module featuring the brand-new OZMO™ Pro Mopping System, enabling robots to deal with stubborn stains 5X efficient than human[2] by using electrically powered high-frequency vibration, and a unique fine mopping mode comparable to an electronic mop, which makes it the most powerful mopping ability in its kind[3]. Alternatively, ECOVACS’ signature mopping technology still be available with its OZMO™ Mopping System, featuring an electronically controlled water pump and 240 ml large water tank, ensures long-lasting mopping efficiency by tackling dirt and dried liquid to offer a smooth and consistent clean. What’s more, the OZMO™ Mopping System can remove over 99%[4] of bacteria based on the test report from a Japanese testing agency.

With a larger battery of 5200 m(A)h, DEEBOT OZMO T8 AIVI can work for three hours and clean large areas of up to 300 sqm easily. The robot’s carpet detection technology allows it to automatically increase suction power on carpets when vacuuming and avoid carpets when mopping, keeping the cleaning experience completely automated.

When paired with the ECOVACS Home App, or smart home devices such as Amazon Echo/Dot and Google Home, users can also control the robot remotely. The intuitive robot will manage its own updates adding new features and functions in the future by using OTA technology. Users can update the App to get the optimized functions.

In addition, with the real time camera acting as an on-demand video manager for the entire house, users can choose to use it for watching the home and monitoring the status of pets, children, or elders in their house anytime and anywhere through the ECOVACS Home App.

Power-up Kit

As part of the launch of the DEEBOT OZMO T8 family, another power-up kit will soon be introduced to enhance overall cleaning performance and user experience. The Auto-Empty Station which cleans the robot’s dustbin automatically after cleaning. The station’s disposable dust bag holds up to 30 days of dirt and debris to dramatically reduce the need to frequently replace the dust bag, so that users can enjoy cleaning homes for weeks without the hassle of dumping the bag.

Pricing and Availability

The DEEBOT OZMO T8 AIVI is available today on Lazada for SGD 729. For more information, please visit ecovacs.com or connect with us on Facebook [https://www.facebook.com/ecovacs.sg/]. More products from the DEEBOT OZMO T8 family will be released later this year.

|

[1] The First DEEBOT with dToF Laser-based Sensors |

|

[2] Test from HQ Laboratory, 100 wipes/min by Hand-wiping, 480 wipes/min by OZMOTM Pro |

|

[3] Test from HQ Laboratory, The Strongest Ability of Moving Stubborn Stains Away with OZMOTM Pro |

|

[4] Certified by Hygiene & Microbiology Research Center, Japan, 2019 |

About ECOVACS ROBOTICS

Innovating Since Day One – Creating the Intelligent Home.

At ECOVACS ROBOTICS, we care about innovating solutions to enhance your lifestyle. Based on deep understanding of use cases and consumer experiences, we design robots that help you to "live smart, enjoy life".

With over 20 years of design and industry-leading research, we have led the market as homes become more intelligent and responsive. We are building a world where your home asks less of your attention, becomes more seamless and powerful, and frees you to spend more time doing what you love.

Media Contact

ECOVACS ROBOTICS

APAC Marketing

Christy Chau

+852-3700-2001

[email protected]

Photo – https://photos.prnasia.com/prnh/20200525/2812433-1-a?lang=0

Photo – https://photos.prnasia.com/prnh/20200525/2812433-1-b?lang=0

Related Links :

http://ecovacs.com