Specialists in SEA, China science & biotech equipment market to expand YES’s global reach FREMONT, Calif., Dec. 7, 2020 — YES (Yield Engineering Systems, Inc.), a leading manufacturer of process equipment for semiconductor advanced packaging, Life Science and "More-than-Moore" applications, today announced that it has signed an agreement with Gaia Science…

Zoomlion Wows at bauma China 2020 Exhibition with Launch of Next-Gen Intelligent Construction Machinery Securing Over $US3 Billion in Orders

SHANGHAI, Nov. 27, 2020 — Zoomlion Heavy Industry Science & Technology Co., Ltd. (Zoomlion) has presented its largest outdoor exhibition at bauma China 2020 in Shanghai and launched multiple high-end intelligent products during the three-day international trade fair. Zoomlion Wows at bauma China 2020 Exhibition…

Cyient Collaborates with SR University to Help Advance the Field of Additive Manufacturing

HYDERABAD, India, Oct. 20, 2020 — Cyient, a global digital engineering and technology solutions company, has signed an MoU with Warangal-based SR University, a leading institution in research and academics. As part of this collaboration, Cyient will help SR University in developing an industry-oriented…

RS Components launches 94% efficient POL converters covering most standard bus and battery voltages

Versatile switching regulators are drop-in replacements for LMxx devices SHANGHAI, Oct. 16, 2020 — RS Components (RS), a trading brand of Electrocomponents plc (LSE: ECM), a global omni-channel solutions partner for industrial customers and suppliers, has added the new TRACO Power TSR-WI Series of non-isolated POL (point of load) DC/DC…

Picosun’s ALD technology boosts UVC LED performance

ESPOO, Finland, Sept. 24, 2020 — Picosun Group, the leading supplier of AGILE ALD® (Atomic Layer Deposition) thin film coating technology, reports excellent results in UVC (ultraviolet-C) LED performance, achieved with the company’s ALD solutions. Excellent reliability and lifetime improvements of UVC LEDs have been obtained at Picosun’s customer and…

Xinhua Silk Road: WIEIE 2020 kicks off in Changzhou, China

BEIJING, Sept. 18, 2020 — The 2020 World Industrial and Energy Internet Expo & International Industrial Equipment Exhibition (WIEIE 2020) kicked off on Wednesday in Changzhou, Jiangsu Province, China, aiming to provide an exchange and cooperation platform for industrial development of industrial Internet, energy Internet, smart city and advanced manufacturing technology….

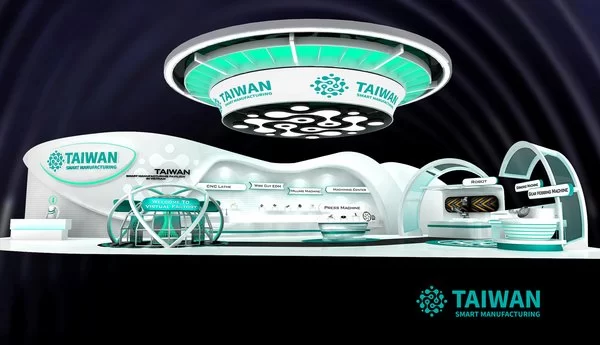

Open invitation to Vietnamese automotive and motorcycle buyers to participate in the Taiwan Smart Manufacturing Pavilion Online Exhibition

TAIPEI, Sept. 2, 2020 — In response to the enduring impact that the pandemic is wielding on international trade and on the world’s leading trade shows, the Taiwan Smart Manufacturing Pavilion Online Exhibition was recently launched in order to safely link up industry players from Taiwan who cannot meet with…

North Star Imaging Moves To A Purpose-Built Imaging Facility In California

An Expanded Industrial X-ray Inspection Services Business in Aliso Viejo ALISA VIEJO, California, Sept. 1, 2020 — North Star Imaging is proud to announce the move of its West Coast Inspection Services business to a much larger testing facility in Aliso Viejo, California….

High customer satisfaction with Picosun’s new service and support model

ESPOO, Finland, Aug. 31, 2020 — Picosun Group’s growth strategy is based on strong expansion into industrial ALD markets. To support this strategy, special emphasis has been placed on strengthening the Group’s global service organization. The investment has paid itself back in the form of high level of customer satisfaction,…

/C O R R E C T I O N — Infineon/

In the news release, "Accurate, anonymous, contactless: Infineon’s radar-based entrance counter solution for public buildings, retail stores, restaurants or corporate spaces", issued on July 28, 2020 by Infineon over PR Newswire, we are advised by the company that the dimension of the discrete rada board…