STOCKHOLM, Oct. 2, 2021 — Mycronic’s Global Technologies division has divested Automation Engineering, Inc. (AEi) to Singapore-based ASM Pacific Technology. AEi, which was acquired by Mycronic in 2016, develops,…

CATL and BASF have signed a framework agreement to accelerate the achievement of global carbon neutrality goals

The cooperation is focused on cathode active materials and battery recycling The partnership supports both companies’ commitment to global carbon neutrality and CATL’s localization strategy in Europe NINGDE, China, Sept. 16, 2021 — Contemporary Amperex Technology Co., Limited (CATL) and BASF SE (BASF) announced a strategic partnership…

MediaTek Announces Kompanio 900T to Enhance Computing Experiences for Tablets and Notebooks

Kompanio family allows OEMs to build powerful, thin and lightweight mobile computing devices with long battery life HSINCHU, Taiwan, Sept. 10, 2021 — MediaTek today announced its new Kompanio™ 900T chipset, expanding MediaTek’s portfolio of mobile computing solutions for tablets, portable notebooks and other devices. The introduction of Kompanio 900T…

INFiLED Launches Cutting Edge Outdoor LED Rental Solution TITAN-X

SHENZHEN, China, Aug. 31, 2021 — INFiLED, leading global manufacturer of LED displays, is delighted to officially announce the launch of its new cutting-edge outdoor rental solution, TITAN-X, after several months of hard work and dedication. As part of the INFiLED DNA, the idea behind the TITAN-X innovation is to…

Mycronic receives order for an SLX system

STOCKHOLM, Aug. 27, 2021 — Mycronic AB (publ) has received an order for an SLX system from a new customer in Asia. The order value is in the range of USD 4-6 million. Delivery of the system is planned for the third quarter of 2022. The SLX laser mask…

JCET 1H 2021 Net Profit Jumps 261%, Earnings Surpass FY 2020 Mark

Q2 2021 Financial Highlights: Revenue was RMB 7.11 billion, an increase of 13.4% year on year. A record high second quarter in the company’s history. Generated RMB 1.68 billion cash from operations, an increase of 67.1% year on year….

Macronix ArmorFlash NOR Flash Earns PSA Certified Level 1 Status

NOR Flash Achieves Security Consortium’s Device-Level Certification HSINCHU, Aug. 16, 2021 — Macronix International Co., Ltd. (TSE: 2337), a leading integrated device manufacturer in the non-volatile memory (NVM) market, today announced its ArmorFlash™ MX75 series NOR Flash received PSA Certified Level 1 status at the device level, where the NOR…

Hänssler Group Achieves Great Reproducibility of ESD Performance and Dimensional Accuracy Using Kimya’s ABS-ESD on Ultimaker S5

UTRECHT, Netherlands, Aug. 10, 2021 — Ultimaker, the global leader in professional 3D printing, today announced that Hänssler Group, German experts in sealing technology, plastics technology and additive manufacturing, uses the Ultimaker S5 and Kimya’s ABS-ESD to cost-effectively produce 300 highly accurate…

Macronix and Foxconn Sign Asset Transaction Agreement for 6-inch Wafer Fab

HSINCHU, Aug. 6, 2021 — Macronix International Co., Ltd. ("Macronix") (TWSE: 2337), a leading integrated device designer and manufacturer in Non-Volatile Memory (NVM), and Hon Hai Technology Group ("Foxconn") (TWSE: 2317), the world’s largest electronics manufacturer and service provider, today announced the signing of an Asset Transaction Agreement for the sales…

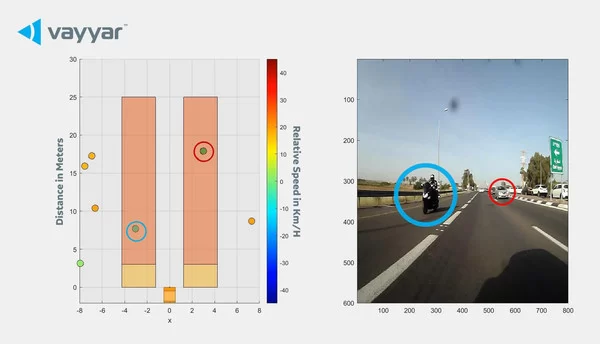

Piaggio Fast Forward Develops New Sensor Technology for Consumer and Enterprise Robots and for Motorcycle and Scooter Safety (ARAS)

TEL AVIV, Israel, Aug. 5, 2021 — Piaggio Fast Forward Develops New Sensor Technology for Consumer and Enterprise Robots and for Motorcycle and Scooter Safety (ARAS) Highlights: Piaggio Fast Forward (PFF) reveals trailblazing sensor technology for consumer and business robots as well as…